The U.S. Department of Labor has developed an automated occupational information database, O*NET, that identifies and describes work content, work skills, and training requirements for all jobs across the country in all sectors of the economy. Much of the occupational information contained in this report is derived directly from the O*NET database, and supplemented with information from the Bureau of Labor Statistics, Census Bureau, and Labor Market and Career Information.

| Industry | % of Electrical Engineers employed | Annual Growth Rate |

|---|---|---|

| Architectural, engineering, and related services | 22 | 0.88 |

| Electric power generation, transmission and distribution | 10.1 | -0.43 |

| Electronic instrument manufacturing | 6.9 | 0.23 |

| Aerospace product and parts manufacturing | 6.4 | 0.25 |

| Scientific research and development services | 4.5 | 0.57 |

| Semiconductor and other electronic component manufacturing | 4.2 | 0.85 |

| Computer systems design and related services | 4 | 1.93 |

| Building equipment contractors | 2.8 | 0.00 |

| Electrical equipment manufacturing | 2.6 | 2.55 |

| 2022 Statewide average hourly wage | $52.98 |

| 2022 National average hourly wage | $54.83 |

| 2020 National employment | 188,000 |

| 2020 Texas employment | 13,790 |

| Texas projected employment by 2030 | 16,747 |

| Texas projected annual employment and Turnover openings through 2030 | 1,271 |

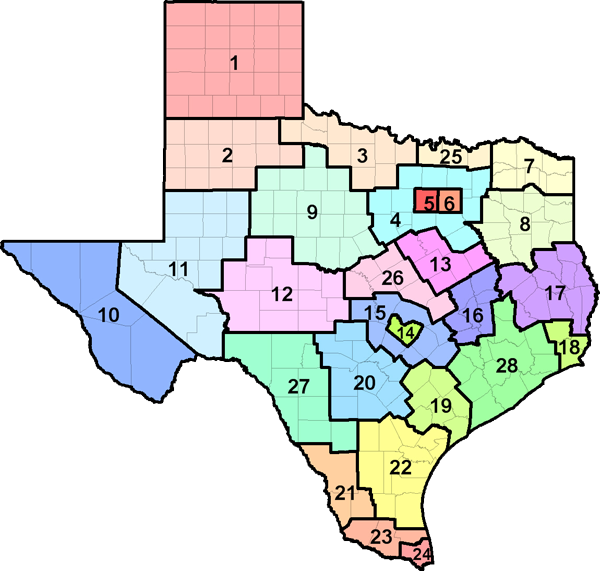

| Region | Employment | Projected Employment 2030 | Projected Annual Openings 2030 |

Annual Growth Rate |

Average Income |

|---|---|---|---|---|---|

| Texas (all regions) | 13,790 | 16,747 | 1,271 | 1.96% | $110,204.00 |

| Top 10 Relevant Knowledge Areas | Relevant Importance Levels |

|---|---|

| Engineering and Technology Knowledge of the practical application of engineering science and technology. This includes applying principles, techniques, procedures, and equipment to the design and production of various goods and services. |

|

| Computers and Electronics Knowledge of circuit boards, processors, chips, electronic equipment, and computer hardware and software, including applications and programming. |

|

| Design Knowledge of design techniques, tools, and principles involved in production of precision technical plans, blueprints, drawings, and models. |

|

| Mathematics Knowledge of arithmetic, algebra, geometry, calculus, statistics, and their applications. |

|

| English Language Knowledge of the structure and content of the English language including the meaning and spelling of words, rules of composition, and grammar. |

|

| Physics Knowledge and prediction of physical principles, laws, their interrelationships, and applications to understanding fluid, material, and atmospheric dynamics, and mechanical, electrical, atomic and sub-atomic structures and processes. |

|

| Production and Processing Knowledge of raw materials, production processes, quality control, costs, and other techniques for maximizing the effective manufacture and distribution of goods. |

|

| Education and Training Knowledge of principles and methods for curriculum and training design, teaching and instruction for individuals and groups, and the measurement of training effects. |

|

| Administration and Management Knowledge of business and management principles involved in strategic planning, resource allocation, human resources modeling, leadership technique, production methods, and coordination of people and resources. |

|

| Mechanical Knowledge of machines and tools, including their designs, uses, repair, and maintenance. |

| Top 10 Relevant Skill Areas | Relevant Importance Levels |

|---|---|

| Reading Comprehension Understanding written sentences and paragraphs in work-related documents. |

|

| Active Listening Giving full attention to what other people are saying, taking time to understand the points being made, asking questions as appropriate, and not interrupting at inappropriate times. |

|

| Writing Communicating effectively in writing as appropriate for the needs of the audience. |

|

| Complex Problem Solving Identifying complex problems and reviewing related information to develop and evaluate options and implement solutions. |

|

| Critical Thinking Using logic and reasoning to identify the strengths and weaknesses of alternative solutions, conclusions, or approaches to problems. |

|

| Speaking Talking to others to convey information effectively. |

|

| Monitoring Monitoring/Assessing performance of yourself, other individuals, or organizations to make improvements or take corrective action. |

|

| Active Learning Understanding the implications of new information for both current and future problem-solving and decision-making. |

|

| Operations Analysis Analyzing needs and product requirements to create a design. |

|

| Mathematics Using mathematics to solve problems. |

| Top 10 Relevant Abilities | Relevant Importance Levels |

|---|---|

| Oral Comprehension The ability to listen to and understand information and ideas presented through spoken words and sentences. |

|

| Written Comprehension The ability to read and understand information and ideas presented in writing. |

|

| Problem Sensitivity The ability to tell when something is wrong or is likely to go wrong. It does not involve solving the problem, only recognizing that there is a problem. |

|

| Deductive Reasoning The ability to apply general rules to specific problems to produce answers that make sense. |

|

| Written Expression The ability to communicate information and ideas in writing so others will understand. |

|

| Information Ordering The ability to arrange things or actions in a certain order or pattern according to a specific rule or set of rules (e.g., patterns of numbers, letters, words, pictures, mathematical operations). |

|

| Category Flexibility The ability to generate or use different sets of rules for combining or grouping things in different ways. |

|

| Oral Expression The ability to communicate information and ideas in speaking so others will understand. |

|

| Inductive Reasoning The ability to combine pieces of information to form general rules or conclusions (includes finding a relationship among seemingly unrelated events). |

|

| Near Vision The ability to see details at close range (within a few feet of the observer). |